In-mine drilling

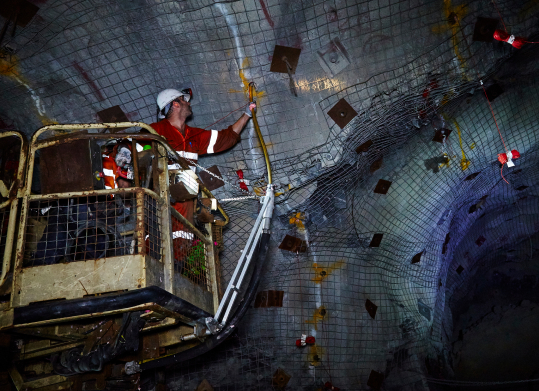

The information gained from drilling helps mine geologists estimate the amount of gold within the ore bodies and is used to generate underground designs to extract that ore. At Fosterville Gold Mine, drilling geologists work specifically with underground diamond drill rigs.

Designing the drill program

Before drilling begins Geologists decide where to drill, how many holes are necessary, how long the holes will be, what the target is, and what the best location is to drill from.

Hole plan given to drillers

Once drilling has begun, down hole surveys are taken regularly, which allows geologists to track the hole. Geologists work closely with drillers to manipulate drilling techniques and vary equipment to reach the desired spacing between drill holes.

Drill core logged

Once drilling is completed, geologists log the drill core. If the hole contains important structures, mineralisation or gold, these areas are sampled by logging geologists.

Reporting the results

Samples are sent to a local laboratory to determine how much gold the rock contains. When results are returned, they are subjected to quality control. If the results pass all tests, they are reported and utilised to build resource and reserve models. Engineers then use these to evaluate the validity of mining.